Lift Equipment Leadership

We specialize in manufacturing and procuring industry-leading lifting solutions—floor jacks, jack stands, support stands, and transmission jacks—engineered for durability and performance. Through agile processes, transparent collaboration, and uncompromising quality, we help make your shop productive and reliable.

About Us

History

Our company broke ground in January 2022, with the goal of manufacturing high-quality lifting equipment at fair costs.

We are named SATURN as a nod to our modern facility and our mindset of “reaching for the stars!”

In June 2022, we produced our very first product, our 3 Ton Professional-grade floor jack.

By 2024, Saturn had ramped up to full-scale production, manufacturing thousands of jacks each month.

Today, Saturn manufactures not only premium floor jacks but also jack stands, utility stands, and transmission jacks.

Customers

Saturn products are sold across North America with high-profile customers, and we have the capability to reach markets worldwide.

We manufacture products for leading Professional Tool & Equipment brands that are very well known in the automotive market.

While Saturn primarily partners with companies that sell to distributors, dealers, retailers, and other channels, we also have the flexibility to transact directly with the ultimate seller of the product.

Mission

At Saturn, our mission is to deliver world-class lift equipment at competitive costs for our customer partners.

We prioritize meeting all quality specifications consistently while maintaining fair pricing. Our goal is 95% on-time delivery with lead times of no more than 70 days.

Saturn empowers global customers to grow and strengthen their lift equipment business.

Our Operations

Location

Our Saturn Manufacturing Campus is located in the South of Vietnam, in the Vinh Long Province.

We are only a two-hour drive from Ho Chi Minh City and a 15-minute drive from Vinh Long City

Vertically Integrated

The Saturn Campus manages nearly all the processes needed to make Pro-Grade Lift Equipment. While other factories outsource many processes, Saturn keeps the processes in-house for the best quality and cost.

Processes in our Saturn campus include Laser cutting, Steel Punching/Bending, Welding, Smoothing, Paint/Powder Coat, Floor Jack Hydraulic Power Unit (HPU) machining, cleaning, and assembly.

Capabilities

Saturn manufactures hundreds of thousands of units of Lift Equipment per year. We have the capacity to add additional volume and are open to new business opportunities.

We can meet and exceed all pro-grade specifications- industry/government mandated and otherwise.

We generally require 4 months to “on-board” a new item, and then 70 days Lead Time on “run-rate” orders.

Our Quality

Culture

At Saturn, we started by making Pro-Grade Lift Equipment. Our team is passionate about consistently building high-quality products.

Our team has over 100 years of Lift Equipment experience in the areas of Engineering, Specification, and Testing.

While our costs are competitive, we do not cut corners on quality and performance!

Testing

Our facility is equipped with state-of-the-art testing systems, enabling comprehensive life cycle and performance evaluations directly on-site.

We also partner with a third-party testing agency to observe and verify our processes, ensuring compliance and accuracy. In addition, we collaborate with a U.S.-based firm equipped with a comprehensive range of lifting test equipment.

We conduct rigorous testing for strength, lifecycle durability, leak-down performance, and packaging integrity—covering every critical aspect of product reliability.

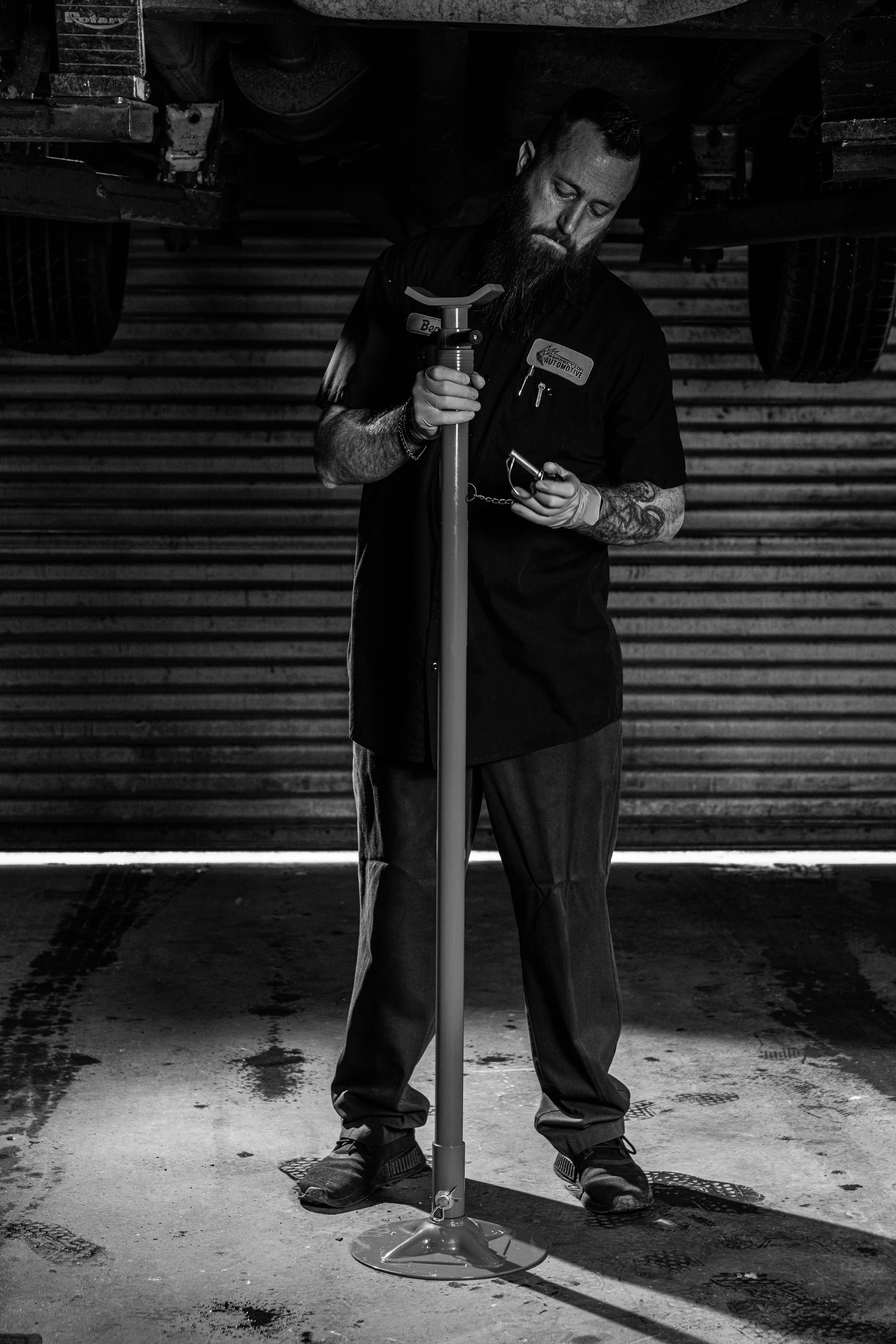

On The Floor

Our Test Labs verify quality and troubleshoot as needed. But real quality occurs on the Saturn plant floor and throughout the production processes.

Each Floor Jack Hydraulic Power Unit (HPU) undergoes at least three inspections during production, including testing in a clean room and verification with microscopic cameras.

The final assembly is tested multiple times before being boxed and shipped to customers.

Our Product

At Saturn, we have manufacturing capabilities for many forms of automotive lifting, including Floor Jacks, Jack Stands, Support Stands, and Transmission Jacks. Please take a look at our catalog offering below within these categories.

Below is a snapshot of the high-quality products we manufacture. If you don’t see exactly what you’re looking for, don’t worry—we’re here to help. Our team can work with you to provide the tools and equipment you need to keep your operations running smoothly. Reach out to us anytime—we’d be happy to assist!

Floor Jacks

1.5 Ton(1,360 kg) Aluminum Floor Jack

Lightweight Aluminum Design - Engineered 25% lighter

Low Profile Frame - Greater Access for Low Clearance Vehicles

Lift Range - 3.5" - 14" (8.9 cm - 35.6 cm)

Integrated Carry Handle

Complies with ASME PASE Safety Standards

Rubber Saddle Pad Insert and Foam Bumper Handle

3 Ton(2,721 kg) Hybrid Floor Jack

Hybrid Design - Aluminum & steel frame, strength, and lightweight

Dual Pump Pistons -Quickly raise the saddle to the load for efficient lifting

Reinforced Lift Arm - Added strength improves chassis control

Low Profile Access - Reach under lower vehicles with minimum height

Lightweight Design - Only 58 lbs (26.3 kg) for easier transport and setup

3 Ton(2,721 kg) Aluminum Floor Jack

Lightweight Design for Racing Enthusiasts and Quick Performance Seekers

Hydraulic Power Unit with Dual Pump Pistons

Lift Range - 3.85" - 19.4" (9.8 cm - 49.3 cm)

Thick Frame Side Plates and Reinforced Lift Arm

Upgraded Power Unit with High-Performance Seals and Hydraulic Fluid

3 Ton(2,721 kg) Low Profile Steel Floor Jack

High-grade steel construction delivers exceptional strength and stability.

Durable powder-coated finish resists wear for long-lasting performance.

Low-profile, long-reach frame accesses tight lift points with precision.

Wide lift range from 3.3" - 20.3"(8.4 cm - 51.6 cm) fits a large assortment.

Dual-Piston hydraulics lift faster with less effort.

3 Ton(2,721 kg) Steel Garage Floor Jack

High-grade steel construction provides superior strength and stability.

Powder-coated finish resists wear for long-lasting durability.

Dual-Piston hydraulics lift faster with less effort.

Lift range from 5.17" - 18.62"(13.1 cm - 47.3 cm) adapts to small and large vehicles.

2-piece handle with knurled grip and bumper for comfort and control.

3.5 Ton(3,175 kg) Low Profile Steel Floor Jack

Low-profile frame fits under low ground clearance vehicles.

7,000 lb. (3,175 kg) lifting capacity for heavy-duty jobs.

Quick-lift dual pump pistons raise the saddle fast.

Bypass and overload valves prevent over-extension and overload.

Complies with ASME PASE Safety Standards

Jack Stands

3 Ton(2,721 kg) Ratcheting Jack Stands

Used in pairs to support automotive vehicles after lifting

Four-legged steel base with pads for stability.

Iron support column with ratchet teeth provides multiple height positions.

Self-Locking handle and pawl secure the column in place.

Large saddles with locating lugs provide support and convenience.

6 Ton(5,443 kg) Ratcheting Jack Stands

Used in pairs to support automotive vehicles after lifting

Four-legged steel base with pads for stability.

Iron support column with ratchet teeth provides multiple height positions.

Self-Locking handle and pawl secure the column in place.

Large saddles with locating lugs provide support and convenience.

10 Ton(9,071 kg) High Height Pin Style Jack Stands

Heavy-duty capacity supports up to 10 tons per pair.

Four-leg steel base delivers strength and stability.

Heavy-schedule steel tube built for demanding shop use.

Adjustable height from 28.1" – 46.5" (71.4 cm – 118.1 cm).

Tethered height pins help prevent loss during use.

22 Ton(19,958 kg) Pin Style Jack Stands

Four-leg steel base and heavy-schedule tube for strength and stability.

Multiple height holes allow quick, pin-style adjustments.

The tethered height pin helps prevent loss during use.

Large saddle with locating lugs positions vehicle frames securely.

Flat base with V-saddle cradles axles and under-truck components.

Support Stands

1,500 lbs.(680 kg) Quick Adjust Support Stand

Spin handle with ACME® screw enables smooth, precise height adjustment.

The five-position locking pin allows fast height setup and fine-tuning.

2.5" x 5.2"(6.3cm x 13.2 cm) saddle supports a wide range of components.

Ideal for suspension, steering, brake, and accessory installations.

Height adjusts from 57" - 78"(144.8 cm - 198.1 cm) for use on lifted vehicles.

1,500 lbs.(680 kg) Short Height Support Stand

3/4-ton(680 kg) capacity supports up to 1,500 lb. components securely.

Short design ideal for waist- and chest-height lift work.

Bearing-mounted spin handle adjusts smoothly under load.

Self-locking ACME® screw ensures precise, secure height changes.

Height adjusts from 35.25" - 57.5"(89.5 cm - 146 cm) for use on lifted vehicles.

1,500 lbs.(680 kg) Standard Height Support Stand

12"(30.4 cm) round base provides stability with a slim profile for tight spaces.

Contoured saddle securely supports exhausts, shocks, and components.

Bearing-mounted spin handle adjusts smoothly, even under load.

Self-locking ACME® screw ensures safe, slip-free height changes.

Height adjusts from 53" - 79"(134.6 cm - 200.6 cm) for use on lifted vehicles.

Transmission Jacks

1,000 lbs.(453 kg) Transmission Jack

1,000 lb(453 kg) Capacity - Designed for efficient removal and installation of vehicle transmissions

Hydraulic Operation - Hands-free foot pedal raises both telescoping stages for smooth lifting

Universal Saddle - Four angle brackets quickly adapt to various transmission pan configurations

Full Tilt Control - Tilts forward 43°, backward 24°, and 37° side-to-side for maximum alignment flexibility

Max Lift Height - Reaches a height of 74.2"(188.5 cm)

Become a Partner

Saturn sells to Lift Equipment companies all over the world. These companies range from large National Tool & Equipment Distributors to Industrial Distributors to Retailers. We are able to partner with new customers across the globe. If you are interested in learning more about what Saturn can do for you, please contact us using this form and select Customer from the drop-down menu.

Customers

Our Saturn facility procures components from many quality parts suppliers throughout Vietnam and other Asian countries. If you feel your company may be able to support Saturn with parts, tooling, or equipment that are used with Lift Equipment, please contact us using this form and select Supplier from the drop-down menu.